1. Shiri don gogewa:ci flexo pressa halin yanzu, ana amfani da roba mai jure mai mai polyurethane, mai jure wuta da siliki na roba mai juriya tare da taurin matsakaici da laushi. Ana ƙididdige taurin ƙura a cikin taurin Shore. Gabaɗaya sun kasu kashi huɗu, digiri 40-45 sune ƙananan tauri, 50-55 digiri ne masu laushi masu laushi, 60-65 digiri ne masu tsini masu matsakaici, kuma 70-75 digiri ne masu gogewa. Dandalin bugu ya kamata ya yi amfani da ƙwanƙwasa tare da babban tauri, kuma kauri na ƙwanƙwasa ya kamata ya zama 10-12mm. Tsawon scraper ya dogara da girman firam ɗin allo, gabaɗaya 20-30mm ya fi faɗin bangarorin biyu na hoto.

2. Bugu na ƙarshe. Nemo layin ƙa'ida mai kyau kuma ƙayyade nisan yanar gizo. Ana buƙatar tazarar allo gabaɗaya don zama daidai. Don cimma daidaitattun buguwa mai kyau, ya kamata a saita tazarar allo ƙasa, kusan 3-4mm, ƙaramin firam ɗin ya kamata a saita a 2-3mm, kuma ana iya saita babban tsari a tsayin 5-6mm. Ana ƙayyade ma'auni na nisa na raga bisa ga girman girman allo da kuma matsananciyar ragamar da aka shimfiɗa.

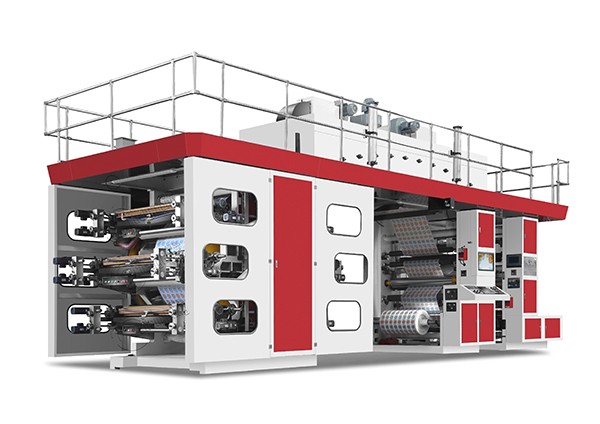

Saboda haka, yin aiki mai kyau na daidaitawaflexographic bugu injiiya mafi inganci tabbatar da ingancin daflexographic bugu inji, don biyan buƙatun buƙatun mutane.

Lokacin aikawa: Jul-07-2022